This former coking plant is part of one of major industrial site in Belgium, located in an area where coal and steel once were the wealth of its region. It was put into service in 1952 by the Forges de la Providence, before going under the ownership of other steel groups, to fed the nearby blast furnace with coke.

Unfortunately, the high level of pollution was no more in compliance with environmental rules. Following numerous complaints, the management simply decided to put an end to the activity of the coking plant rather than to rebuild or re-adapt it to the standards of the day. Finally, the factory closed in January 2008.

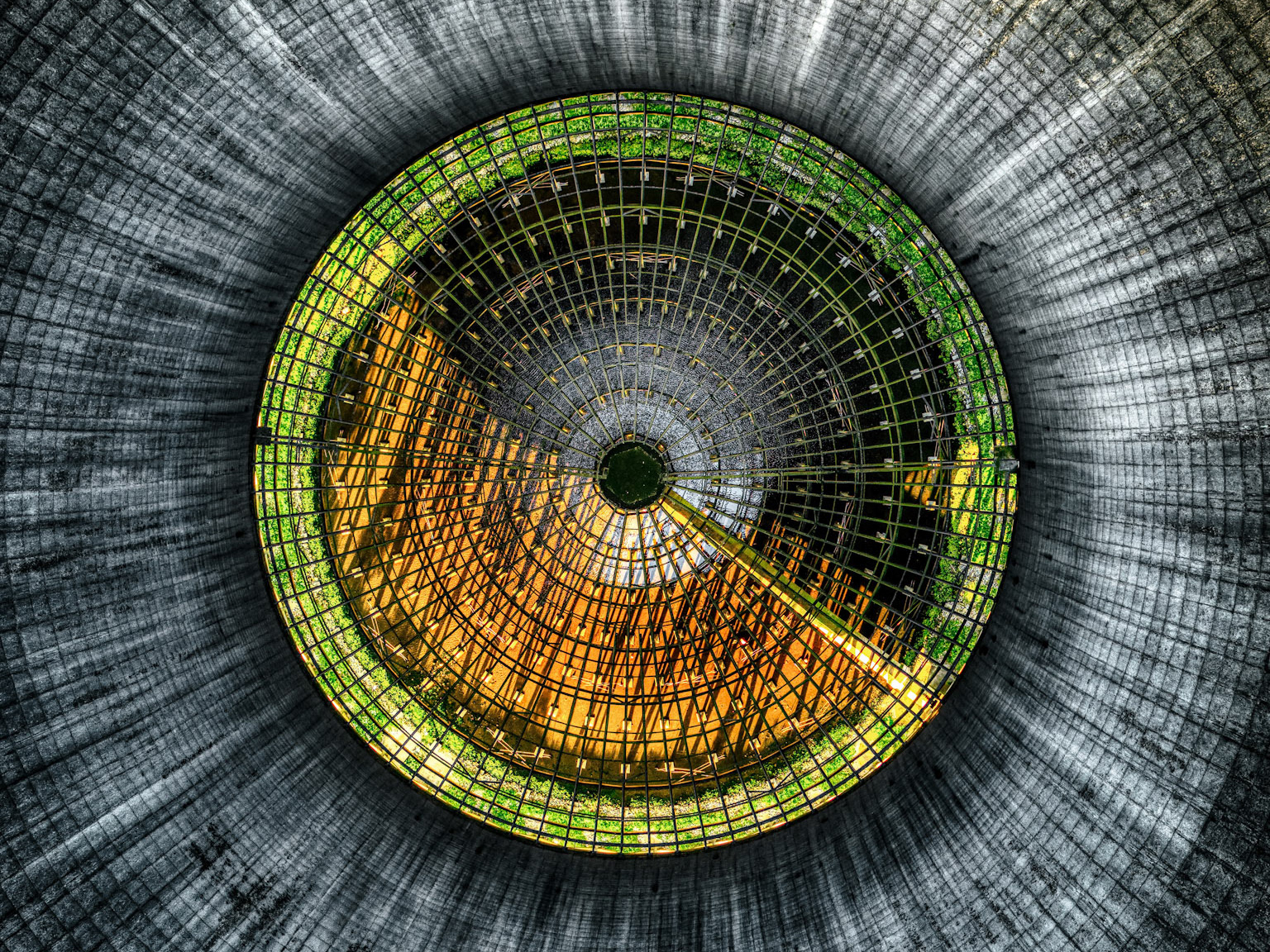

Today, the site is kind of abandoned, though severely guarded. Its demolition and de-pollution process is progressing slowly.

Coke Batteries

To make steel in a blast furnace, coal must first be turned into coke. Coke has a dual role in the steelmaking process. First, it provides the heat needed to melt the ore, and second, when it is burnt, it has the effect of ‘stealing’ the oxygen from the iron ore, leaving only the pure iron behind.

The coal is heated to 1.250° C in the coke ovens. Since these ovens are oxygen-free, the coal does not actually burn. This process is referred to as ‘dry distillation’. This removes any impurities in the coal, resulting in coke, which is a porous substance that is nearly all carbon. It takes about 18 hours to convert 35 tonnes of coal into 25 tonnes of metallurgical coke.

Continuous Change

The site is gigantic and imposed by its complex structure. This coking plant once was only a small part of that site, which had also a blast furnace, a steelworks, a rolling mill, a power station, etc.

Like many other steel sites, the plant has undergone countless changes over the years to adapt to the industrial boom and the modernization of manufacturing tools. This is how it started with 2 batteries and ended up with 4 batteries for a total of 122 ovens, following major refurbishments in 1981 and 1990.